Streamline Your Product packaging Method using a Vertical Cartoning Machine

In today's fast-paced organizational environment, optimizing production and product packaging procedures is essential for firms to stay competitive. One important aspect of productive product packaging is the application of innovative devices that will automate and enhance the method. One device that has transformed the packaging industry is the Vertical Cartoning Machine. In the following paragraphs, we shall check out the advantages and uses of straight cartooning machines and how they may enhance your product packaging procedures.

Streamlined Packaging with Straight Cartoning Models:

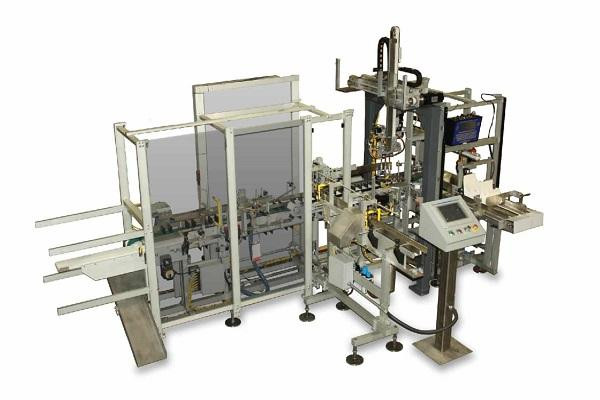

Vertical cartoning machines are professional equipment created to speed up the entire process of constructing, satisfying, and shutting cartons. These machines are widely used across numerous businesses, which include meals and refreshments, pharmaceuticals, beauty products, and consumer products. They offer several positive aspects that contribute to improved wrapping productivity, cost benefits, and improved product or service business presentation.

Improved Pace and Performance:

Straight cartooning equipment is capable of great-speed surgical procedures, drastically raising wrapping throughput. By automating carton erection, product or service installation, and closure procedures, these machines get rid of the need for manual labor, reducing the chances of faults and improving general productivity. With precise and consistent overall performance, they make certain that each carton is correctly filled and enclosed, decreasing product waste materials and maximizing efficiency.

Flexible Packaging Options:

Straight cartooning equipment is adaptable and might take care of a variety of packaging formats, including bottles, blister packs, pouches, pipes, and more. Whether you bundle specific products or pack several items, these machines can easily be tweaked to accommodate various sizes, shapes, and layouts. This overall flexibility permits suppliers to evolve to altering industry demands and branch out their item offerings without investing in more packing devices.

Increased Product Protection and Business Presentation:

With specific control of the packaging method, top-to-bottom cartoning models make certain that merchandise is securely and neatly loaded. The devices can integrate additional features like leaflet insertion, set programming, marking, and tamper-apparent sealing, which not only shield the item but also provide important information and branding elements to consumers. The regular and expert packaging improves the general presentation and recognizes the price of the item.

Enhanced Traceability and Compliance:

Straight cartooning models can integrate with serialization and monitor-and-locate methods, which can be important in market sectors like pharmaceuticals and healthcare units to guarantee merchandise safety and regulatory concurrence. By employing these systems, suppliers can easily trace and authenticate specific items through the supply chain, reducing the chance of counterfeiting and improving client assurance.

Verdict:

In today's competitive marketplace, organizations must embrace innovative packing solutions to stay ahead of the curve. Vertical cartooning equipment provides a selection of benefits, from greater product packaging velocity and efficiency to functional product packaging options and improved product safety. By investing in this innovative machinery, companies can optimize their packaging functions, decrease expenses, boost product business presentation, and ultimately obtain a competitive edge. To learn a great deal about straight cartoning models and other wrapping remedies accessible, pay a visit to AFAsystemsinc.com and take a step towards revolutionizing your wrapping functions.

For more info :-

Source Url :- https://sites.google.com/view/afasystemsincm/home

Comments

Post a Comment